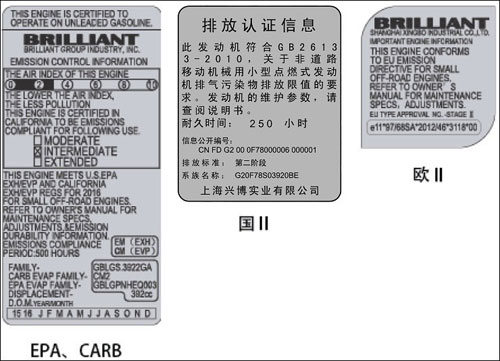

Each Brilliant engine assigned with unique serial number, it includes the information about the product warranty, correct model # for parts ordering and emission information. These remarks are listed as below. Please write down the engine serial number on the owner’s manual for future reference use.

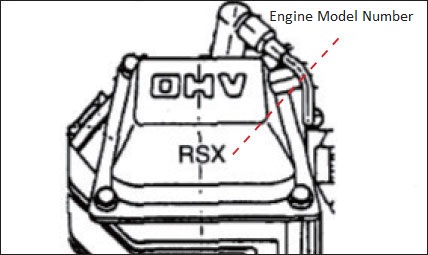

● Unique identification for each brilliant engine model.

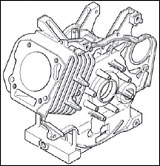

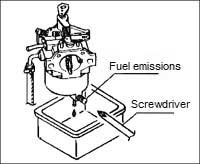

Model number stamped on the head cover.See Picture 1

(Picture 1)

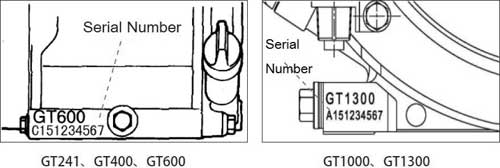

●Every engine has the exclusive serial number

Every engine has the exclusive serial number and engraved on the body case.

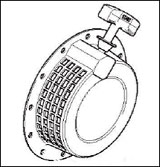

See Picture 2

(Picture2)

To ensure correct operation, please be aware of the emissions regulations territory limits on the emission and warning labels. Regarding other important safety information, please refer to Owner’s Manual for additional info.

●Emission Label

●Warning Label

Before using the engine, please read instruction carefully

Before using the engine, please read instruction carefully

In order to make your engine to operate at the best performance, please read through below instruction. If you need more information, please refer to your Owner’s manual booklet.

- ● Every engine has an exclusive series number.

- ● In order to get the best performance, please use unleaded gasoline.

- ● Please use the gasoline within 30 days after purchasing.

- ● Please do not mix alcohol with gasoline, except approved stabilizer for carburetor preservative.

- ● Please do not overfill the fuel tank, the additional space is required for fuel system circulation, top of the gasoline up to 25mm of tank capacity level.

Gasoline is a flammable and explosive dangerous goods. Please pay extra attention during the operation.

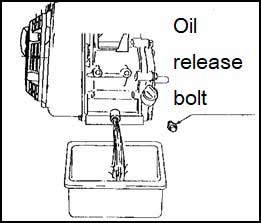

- ● Add and Change lubricating oil

All oil and fuel drained at factory prior to shipping. Before starting the engine, must follow the below instructions to proceed.

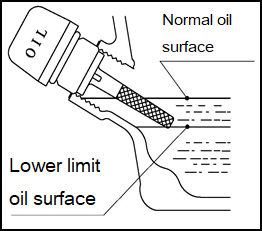

- ▲ Place engine on a balanced surface when adding the oil and doing inspection.

- ▲ To check the oil level, insert the oil gauge without tighten stick to get correct engine oil measurement level.

- ▲ Add the oil up to the marked level shows on oil gauge for correct operation.

- ▲ Before starting, oil gauge must be tighten.

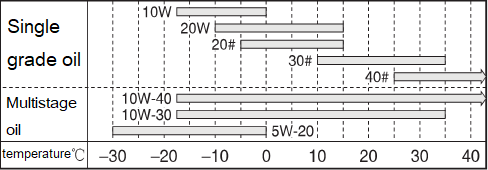

- ● Recommended engine oil: API grade, or equivalent to or higher than SE grade

- Recommended lubricating oil type:

- Use 10W-30 or 10W-40 in the summer or winter condition

- Use 5W-20 in the very cool area

Based actual temperature condition, please use the correct lubricating engine oil for best performance of the engine.

●Precautions

|

▲ Oil level check (loosen oil gauge for correct oil level) |

|

▲ Drain oil (Follow the manual to change oil) ▲ Change the engine oil when the engine is warm Caution of burning |

|

|

▲ Always top of the engine oil |

|

- ●Before starting

- ▲ Check the level of oil and gasoline.

- ▲ Check the air filter condition is clean or clogged.

- ▲ After shut down, gently pull the recoil starter two to three times to return to neutral position for easy start on next use.

- ▲ When starting, ensure all the switchers are on, choke is off, slight opening on the throttle

- ●Precaution in using

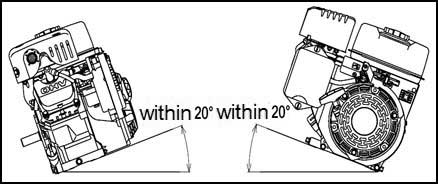

- ▲Inclination is allowed with 20 degree (PTO, Carburetor, Air filter and etc)

- → Avoid the fuel leakage from the tank

- → Avoid uneven surface to effect standard operating RPM.

- → Avoid carburetor leakage from the oil pipe

- → Avoid touching the oil alert and cause the shutdown of the engine.

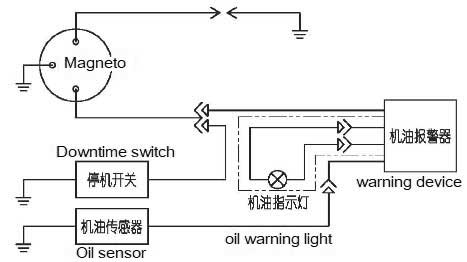

- ▲ Oil Alert

- → When the oil reach below allowed level, it will cause shutdown of the engine.

- → For engine equipment with oil alert light, light will blink when the oil reach below allowed level, and cause shutdown of the engine at the same time.

- → Circuit diagram:

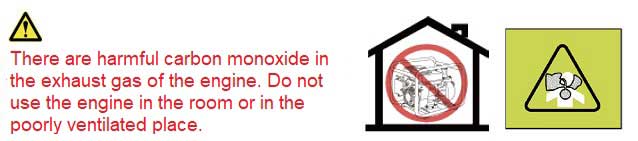

▲ Important safety notice

→Please do not start the engine without reading the manual.

Only trained technician may perform the installation and repair the engine.

→Avoid touching with hand or foot on the working components during operation of use.

→Please do not use or store the engine near any heat source, flame, or the place can/may generates flame and sparks

→Do not smoke or near any source of fire when adding fuel to tank.

→Do not take off the fuel cap or add fuel when engine is under operation or hot.

→Please do not start the engine when fuel leakage is noticed, smell the gasoline or has the explosion risk condition.

→Please do not adjust the engine speed

→Please do not start the engine without muffler or air filter

→Please do not touch high voltage line or spark plug

In order to help you find the correct engine model, reference on purchase, please refer to the below information details. Complete assembling diagram, parts breakdown menu, and customer services details are also provided.

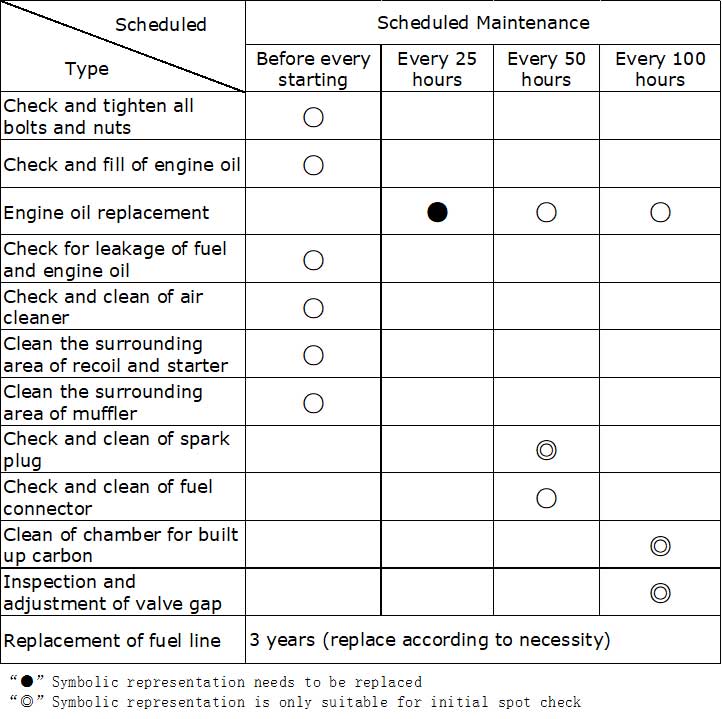

Addition to scheduled maintenance, periodically check up is also needed to keep the engine performance and duration. If you need more information, please refer to your manual.

|

No kindling

Daily checking |

|

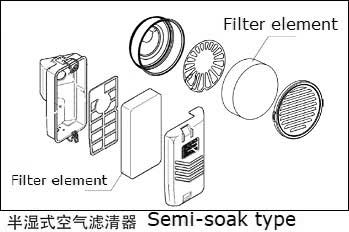

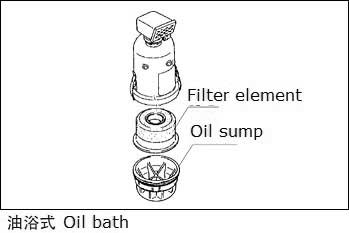

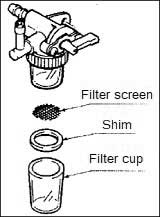

Oil bath type: If the oil level is low, it is added to the normal oil surface. If dirty, cleaning oil and components, components will be immersed in oil, fling off excess oil or squeeze gently after installation. |

|

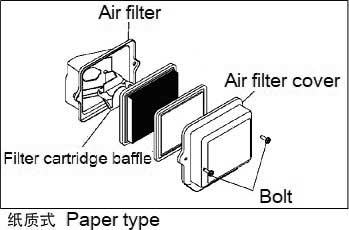

Paper type:

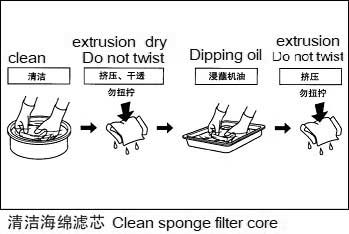

Foam element: If element is heavily clogged or over dry, wash the element with kerosene, air dry the filter, soak in engine oil and squeezing well before install. |

|

|

|

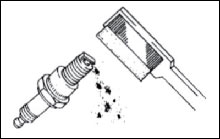

● Cleaning of spark plug

Every 50 hours of operation remove carbon build up on the electrode, clean with sandpaper if necessary. |

|

|

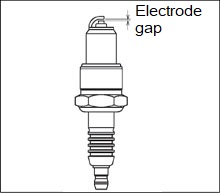

● Adjustment of electrode gap Standard value The electrode burning situation differs according to operation condition (load condition), so when abnormal blackening or excessive burning happen, must replace with hot-type of cold-type spark plug base on the situation. |

|

|

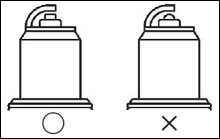

● Spark check Precaution |

|

|

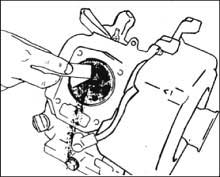

● Cleaning carbon buildup on cylinder head Every 100 hours of operation |

|

|

● Cleaning carbon buildup on piston surface Remove cylinder head, clean around the valve and piston surface |

|

● Remove all kind of buildup such as soil, leaves, oil sludge from the heat sink plate to restore standard performance

| ▼Cylinder box radiator | ▼Cylinder head heat sink | ▼Start the tuyere |

|

|

|

|

● Every 50 hours usage |

|

●Drain fuel in the fuel tank and the carburetor. (Loosen the screw of the carburetor and drain the fuel) ●Remove the spark plug, add a small amout (about 2-3 cc) of engine oil into the cylinder, pull the recoil rope slowly for several times, reinstall the spark plug and release recoil rope when feel having pressure. (neutral point of decompression) ●Clean the surface with oil soaked cloth, store in cool and dry place. |

|

|

It’s the best to use systemize to identify the correct source/reason of engine failure. We listed the general problems and possible cause at below. First of all, find out the problem of the engine. Then, identify the possible cause. Before starting the engine, please follow the safety precaution notice.

For further assistance or question, please contact Brilliant Group Industry Inc. Customer Services at 516-218-2810.

▲Clogged of air cleaner element

● Check of air intake system

→Filter is dirty or clogged?

→Intake has been clogged?

→Choke is closed?

▲Clogging of fuel filter, hose; Carburetor is malfunction (Clogging of spout, fuel nozzle, etc)

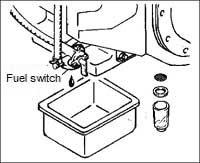

● Check fuel system

→Check fuel switch is on

→Check clogging og of fuel hose, filter

→Check clogging of air vent

→Check clogging of spout and fuel nozzle

▲Check Sparking system (including sparks plug and cable)

● check ignition coil system

→Check if stop switch is “ON”

→Ignition system wire (primary, secondary) of ignition system is disconnected? The cable warp is torn?

→Still no spark with step 1 and 2 above are under normal condition, replacement of new ignition coil will be need.

▲Defective valve gap clearance

● Check compression pressure

→Check if stop switch is “ON”

→Valve gap clearance is normal or not?

→Valve spring loosen or not?

→Valve stand is normal or not? Check for any embed blockage.

→Is the cylinder, piston and piston ring abrasion exceed the limit of usage.

▲ Engine oil below required level.

● check oil system

→Check if oil is lower than standard level.

▲ Speed malfunction check

● Check speed governing system adjustment

→Check adjustment of regulating system is operating correctly.

→Tension strength for speed governing spring

→Smooth movement of desingted parts. (sliding cover, valve throttle, speed governing shaft)

● Check combustion system

→Fuel in the tank is sufficient?

→Fuel hose is crushed or bent? Does it affecting the flowtation of fuel?

→Is there blockage of the air circulation hole on fuel tank and carburetor?

→Is the carburetor idle control screw is in position with correct adjustment?

→Is the carburetor air inlet, gauge hole is clogged or not?

● Check of air intake system

→Air cleaner element is clogged or not?

→Choke valve is fully opened or not?

→Cylinder cover and carburetor flange are sufficient sealed or not?

● Check ignition system

→Spark plug electrode is normal or not?

→Ignition coil is normal or not?

● Check oil system

→Oil is lower than the standard level

▲ Exhaust malfunction check

● Emission of black smoke check

→Choke valve is fully opened or not?

→Air cleaner element is clogged or not?

→Carburetor is over-flowing or not?

● Emission of white smoke check

→Excessively engine oil is over required level.

→Breather valve function is normal or not?

→Piston ring gap position is overlapped or not?

→Piston ring is adhered or broken?

→Is the cylinder, piston and piston ring abrasion exceed the limit of usage.

▲ Abnormal noise malfunction check

● Abnormal combustion noise

→Is inferior quality or lower than required standard grade fuel been used?

→Any blockage at passages of air cooling? Any accumulation occurred as grass or mud nearby recoil system, cylinder and cylinder cover?

→Ignition time is too soon or delay?

→Valve gap clearance is too narrow?

● Abnormal mechanical noise

→Valve clearance is too wide?

→Loosen tension strength on valve spring?

→Are all the bearing, camshaft, and balance shaft geared correctly?

→Gap between cylinder and piston is over required range?

→Gap between Crankshaft pin and connecting rod is over required range?

▲ Speed malfunction check

● Check compression pressure

→Check for leakage on cylinder head gasket?

→Valve gap is correctly?

→Loosen tension strength of valve spring

→Valve stand is normal or not? Check for any embed blockage.

→Is the cylinder, piston and piston ring abrasion exceed the limit of usage.

● Smoke at operation

→The same steps list as the exhaust malfunction check

→The same steps list as the abnormal noise malfunction check

● Equiment and engine pairing check

→Open space for Air filter intake?

→Cooling ventilation is discharged directly to outside of the room

→Carburetor and fuel tank are overheated?

→Muffler exhaust emission is discharged directly to outside of the room

▲ Speed malfunction check

● Visual check on oil leakage

→Is oil seal leaking?

→Any leakage by the gasket?

→Any leakage on body case?

→Any leakage on fuel system (fuel tank, pipe)?

● Compression pressure check

→Piston ring is adhered or broken?

→Is the cylinder, piston and piston ring abrasion exceed the limit of usage.

→Can breather valve operate normally?

→Is the valve and stem abrasion exceed the limit of usage.

→Is the intake valve and stem seal is normal?

● Check of air intake system

→Is filter is dirty, dusted or clogged?

→Intake valve has dust, or embedded blockage?

● Check of fuel system

→Fuel tube, filter is clogged?

→Fuel tank cap air vent is clogged?

→Carburetor spray nozzle, spout, head is clogged?

→Fuel is exhausted?

● Check of engine oil system

→Oil level is much lower than the required standard

Brilliant Group Industry Inc.

159 N. Central Ave,

Valley Stream, NY 11580, USA

Tel:+1-516-218-2810 Fax: +1-516-706-3262

9123 Santa Anita Ave,

Rancho Cucamonga, CA 91730, USA

Tel:+1-909-581-1212 Fax: +1-909-581-1215

E-mail: info@brilliantindustry.com

U.S. Toll Free #.: +1-888-666-0292

Shanghai Brilliant Trading & Development Co., Ltd.

Floor 33, 257 Siping Road, Shanghai 200081, China

Tel:+86-21-6521 2718,Fax:+86-21-6521 4386

Manufacture: Shanghai Xingbo Industrial Co., Ltd.

67 Caoli Road, Fengjing Town, Shanghai 201502, China

Tel:+86-21-5736 4891 Fax:+86-21-5736 1738